Optimized Testing and Validation for Agricultural Equipment Through Simulation

Tirth Agro Technology Private Limited

Overview

Tirth Agro Technology Private Limited is a leading Indian farm equipment OEM. The company was founded in 1997 by a progressive farmer, Mr. Ladhubhai S. Gohil, in Rajkot, Gujarat. While the company’s initial focus was on the production of spare parts, it subsequently launched a complete production line of agricultural implements sold under the ‘Shaktiman’ brand.

Today, Tirth Agro serves its customers through a vast network of over 46 distributors and 700 dealers across the country. The company has established a strong presence in the domestic market with 50 percent of the market share, and has expanded to overseas markets as well.

In agriculture, market sentiment, which is generally linked to monsoons, plays a big role in influencing demand. In most cases, there is only a short three month window where maximum demand occurs. To ensure that demand is met in a timely manner, Tirth Agro needed to speed up its processes considerably right from material acquisition to manufacturing to testing and validation.

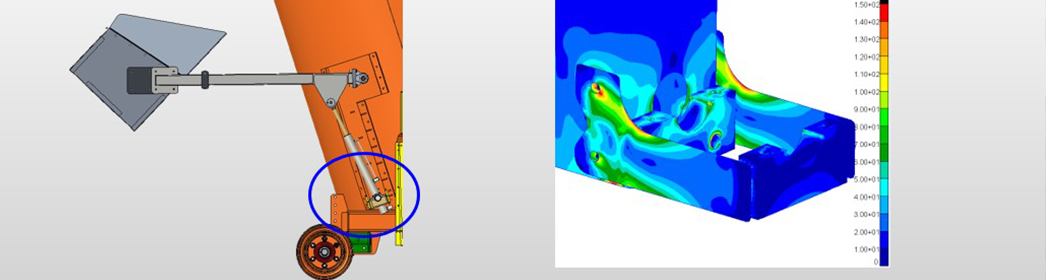

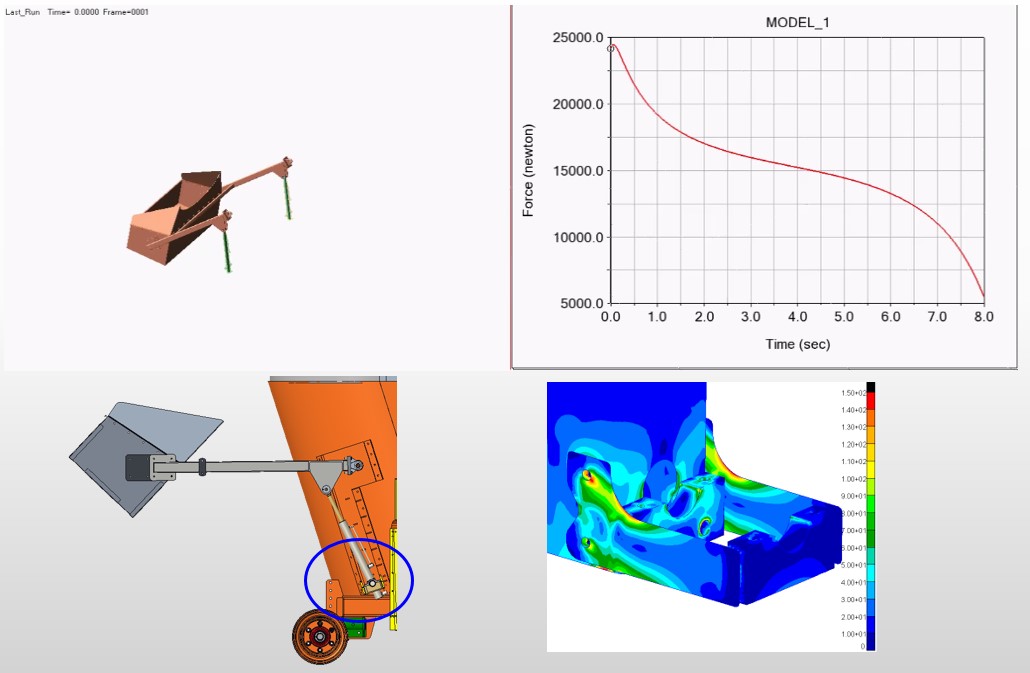

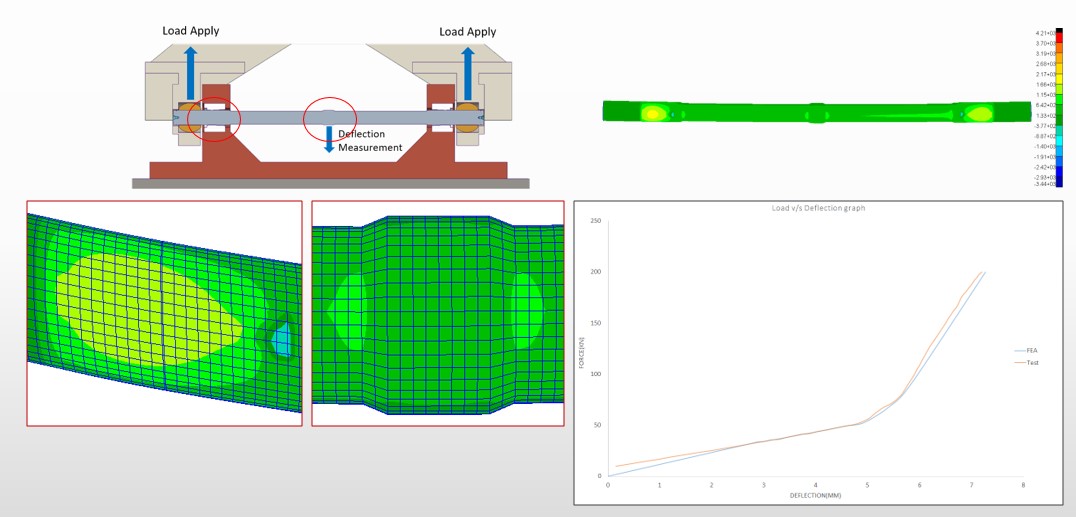

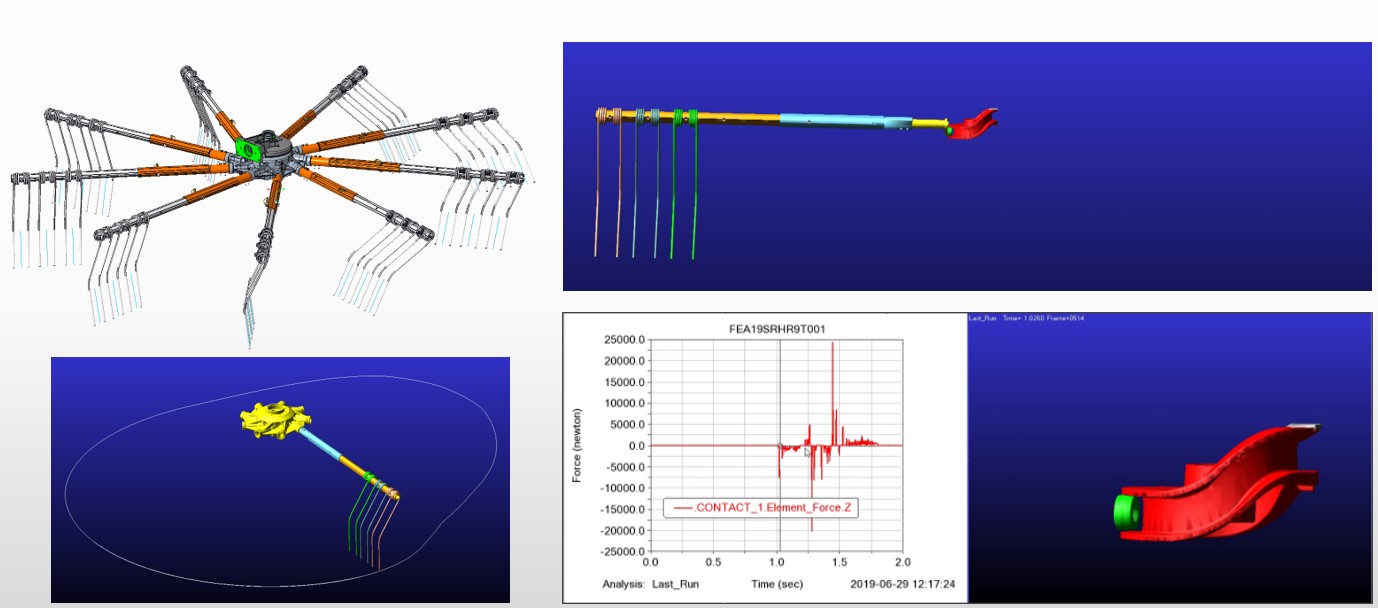

Testing for farm equipment is often more complicated than regular automobile testing since it needs to account for a much wider variety of surfaces and field conditions. With the use of simulation tools from MSC Software, the company sought to optimize and shorten the testing timelines while ensuring top-notch product quality.

Products Used

The team selected MSC Nastran to perform static, dynamic, and thermal analysis across the linear and nonlinear domains. All moving components of the vehicle (which accounted for about 60 percent of the fabricating structure), rotary structures, and heat generation were tested using MSC Nastran. This was complemented by automated structural optimization and embedded fatigue analysis technologies, all enabled by high performance computing.

In addition to MSC Nastran, the team also used other simulation software tools such as MSC Adams, MSC Apex, MSC Patran.

Approach

With the various MSC Software products, the team could test independent components as well as the full machine. This was significant given that the machines typically have fairly complex assemblies that could consist of up to 5000 different parts. The engineers at Tirth Agro were able to develop products with better structural design with the essential strength and stiffness. The team used MSC Nastran to predict the performance and safety of the agricultural machines well in advance, at the product development stage itself.

The SOLIZE India team provided a complete knowledge transfer and comprehensive training to the engineers. SOLIZE also conducted adequate hand holding through the initial phases to ensure that the team was well-equipped to use the software optimally and deliver the required ROI.

Benefits

- While field testing cannot be completely eliminated, the use of simulation and virtual prototyping has helped speed up the testing and validation process significantly.

- The use of simulation increased efficiency, reducing product development time by 20-30 percent.

- Extensive virtual prototype testing helped in bringing down the overall cost and manpower requirements, while easing the physical testing process.

- The number of iterations required during the testing process have reduced by 30-40 percent. The average time for testing has reduced by about one month.

As it continues its endeavor to develop superior quality products, the Tirth Agro team plans to focus on virtual testing for different soil types in the future. They are also considering the adoption of an automation tool kit and CFD solutions.

“As the world’s largest manufacturer of rotary tillers and leading agriculture OEM of India, our focus at Tirth Agro is consistently on developing superior products to serve our customers better. Using the simulation and virtual prototyping tools from MSC Software has helped us make our testing processes much more efficient, enabling us to meet customer demands in a timely and effective manner. The unrelenting support from SOLIZE in terms of training and knowledge transfer has played a big role in facilitating this.”

– Nipul Rajyaguru

Head – IT & SAP, Tirth Agro Technology Pvt. Ltd.

Office address: 2nd Floor, Unit Nos. 201-B & 202, Brigade Opus, No. 70/401, Kodigehalli Gate, Hebbal, Bengaluru- 560092, India