Simulation Solutions

Engineering today moves faster than ever leaving no room for trial and error. At SOLIZE, we help organizations replace physical testing with intelligent simulation, enabling faster validation, better insights, and confident decision-making. Powered by Hexagon’s simulation technologies and VI-grade’s real-time systems, our solutions bring digital precision to every stage of product development.

Hexagon Simulation Solutions

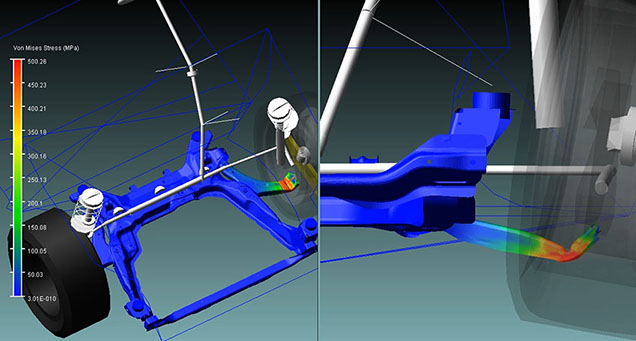

Using Hexagon’s MSC Nastran, Marc, and Dytran, our engineers conduct advanced structural and thermal analyses to ensure products can withstand real-world stresses and environmental conditions. These tools help us simulate complex behavior to conduct static and dynamic load testing to crash and fatigue validation with precision. By replicating the effects of materials, temperature, and impact, we help our customers design safer, stronger, and more reliable systems, all before the first prototype is built.

Applications

- Automotive: Crash, NVH, aerodynamics, and ADAS system simulation.

- Aerospace: Structural, aeroelastic, and fatigue performance analysis.

- Industrial Machinery: Durability and load-bearing optimization for heavy systems.

- Electronics: Thermal and vibration simulation for compact, high-performance devices.

- Energy: Structural and fluid dynamics for renewable systems and power generation.

Applications

Automotive: Crash, NVH, aerodynamics, and ADAS system simulation. Aerospace: Structural, aeroelastic, and fatigue performance analysis. Industrial Machinery: Durability and load-bearing optimization for heavy systems. Electronics: Thermal and vibration simulation for compact, high-performance devices. Energy: Structural and fluid dynamics for renewable systems and power generation.

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Industrial Equipment

Fatigue life prediction for heavy machinery under variable loads.

Energy

Thermal resistance and pressure simulations for pipelines and power systems.

Multibody Dynamics & Systems Simulation

With Hexagon’s Adams and Easy5, we simulate motion and dynamic interactions between mechanical systems to predict real-world performance. These tools enable engineers to visualize how components move, connect, and behave under load. From suspension and control systems to robotic linkages and machinery, multibody dynamics simulation lets teams optimize design, improve durability, and eliminate costly redesigns. It also allows virtual testing of assemblies, reducing physical prototypes and accelerating product maturity.

Applications

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Aerospace

Stress and thermal fatigue analysis for lightweight airframe components.

Industrial Equipment

Fatigue life prediction for heavy machinery under variable loads.

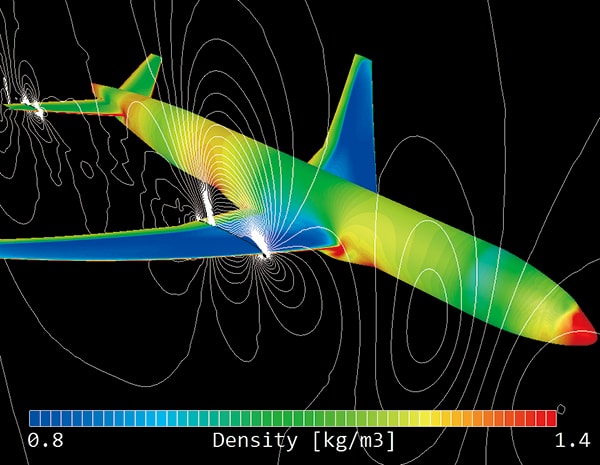

CFD & Multiphysics Simulation

Through Hexagon’s Cradle CFD suite, we perform advanced fluid flow and thermal simulations to understand how products interact with air, water, and heat. Engineers can evaluate performance under complex environmental conditions. Everything from aerodynamics and cooling to convection and turbulence can be analyzed with the upgraded Cradle suite. By integrating CFD into early design, we help teams refine product geometry, improve energy efficiency, and prevent overheating or pressure loss. The result: optimized designs that balance performance with sustainability.

Applications

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Electronics

Stress and thermal fatigue analysis for lightweight airframe components.

Energy

Stress and thermal fatigue analysis for lightweight airframe components.

Industrial Machinery

Fatigue life prediction for heavy machinery under variable loads.

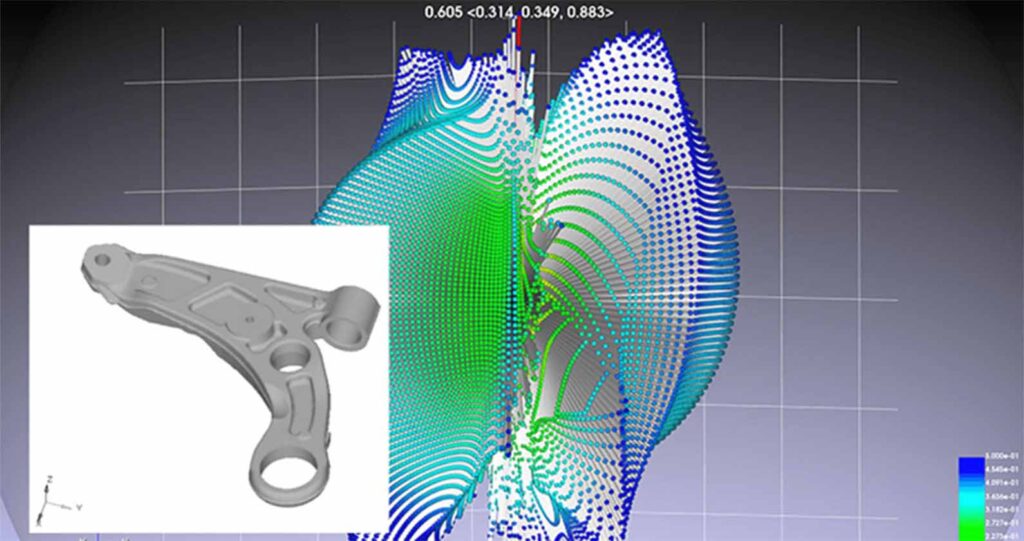

Material Modeling & Durability Simulation

Using Hexagon’s Digimat and MSC Fatigue, we evaluate how materials behave under stress, strain, and cyclic loading. Our simulations assess fatigue life, composite performance, and failure prediction, helping teams design products that last longer with less material waste. This enables the creation of lightweight, durable components that maintain strength and reliability over time. By combining material science with digital validation, we ensure that every design stands up to the test of time.

Applications

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Aerospace

Stress and thermal fatigue analysis for lightweight airframe components.

Industrial Equipment

Stress and thermal fatigue analysis for lightweight airframe components.

Energy

Fatigue life prediction for heavy machinery under variable loads.

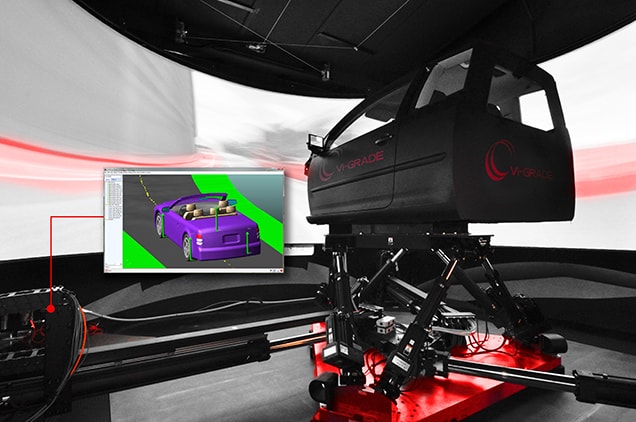

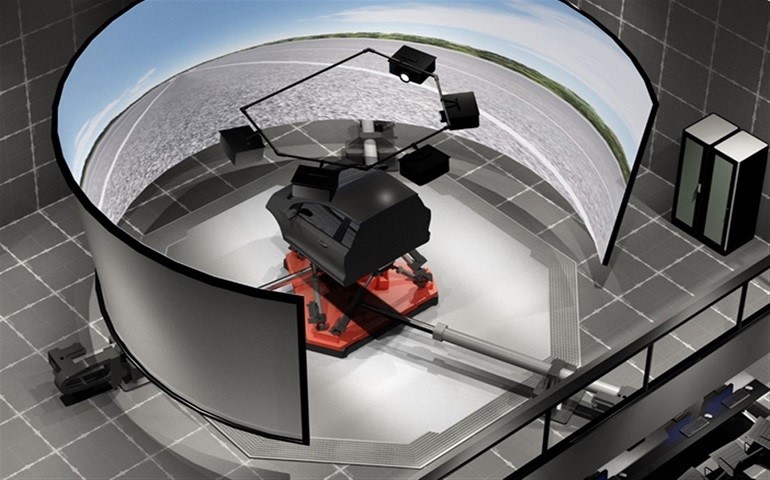

VI-grade Simulation Environment

With VI-grade’s CarRealTime and DriveSim environments, we help customers experience full-scale vehicle dynamics in real time before a single prototype hits the track. These tools create a bridge between digital engineering and physical testing, allowing teams to validate performance, comfort, and control in virtual conditions. Engineers and drivers can interact with vehicle models to assess handling, suspension, and ADAS features, accelerating the development of safe, high-performing vehicles.

Applications

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Motorsport

Stress and thermal fatigue analysis for lightweight airframe components.

Aerospace

Stress and thermal fatigue analysis for lightweight airframe components.

Real-time Vehicle Simulation

With VI-grade’s CarRealTime and DriveSim environments, we help customers experience full-scale vehicle dynamics in real time before a single prototype hits the track. These tools create a bridge between digital engineering and physical testing, allowing teams to validate performance, comfort, and control in virtual conditions. Engineers and drivers can interact with vehicle models to assess handling, suspension, and ADAS features, accelerating the development of safe, high-performing vehicles.

Applications

Automotive

Ride and handling assessment, ADAS system validation.

Motorsport

Track simulation for performance tuning and optimization.

Aerospace

Pilot-in-the-loop simulations for flight maneuver evaluation.

Hardware & Software Integration Simulation

Combining VI-grade’s Driver, Track, and HIL/SIL tools, we integrate simulation with real-world hardware systems for closed-loop validation. This setup allows engineers to test control units, sensors, and actuators in realistic conditions without needing a physical prototype. The result is a faster, safer, and more cost-effective development process where design and testing happen side by side. It’s the foundation for modern digital twins and connected testing ecosystems.

Applications

Automotive

Crashworthiness and impact testing for body structures and safety systems.

Industrial Equipment

Stress and thermal fatigue analysis for lightweight airframe components.

Research & Education

Stress and thermal fatigue analysis for lightweight airframe components.

Why SOLIZE

At SOLIZE, we turn every single test and simulation result into actionable insights. Our engineers bring decades of real-world experience to every project, ensuring results align with your performance, safety, and compliance goals. Whether you’re validating a prototype or creating a full digital twin, our collaboration with full suite of Hexagon and VI-grade software helps you achieve accuracy, agility, and confidence at every stage of development.

Office address: 2nd Floor, Unit Nos. 201-B & 202, Brigade Opus, No. 70/401, Kodigehalli Gate, Hebbal, Bengaluru- 560092, India